|

||

PrimaryMCPCB FR4 Screen Print Liquid Pen |

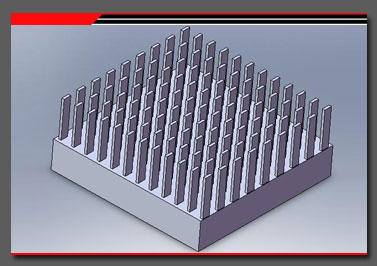

SecondaryHeat Sinks Extruded Cast Stamped Molded |

TertiaryForced - Fan Natural - Heat Pipes Other - Peltier - Liquid |

Thermal

Thermal management is one of the key factors in every LED application and temperature often adversely affects life and overall output. Our design approach is to model the fixture and LED(s) in a simulated environment before we ever make any parts. Using our Finite Element (FE) software, we can quickly move through multiple iterations to optimize the design. Next, we can machine, cast or use SLA models to prototype and test it in our climate-controlled lab. Using data logging equipment to model changes in current and elevated temperatures, we create a 2-D map of exactly what is happening at time 0 to 12 hours. In some applications, 24-hour and multiple day testing are required. All of the above benefits provide our customers with peace of mind that at a wide range of temperatures, their product will not only perform at specified output, but also endure harsh conditions.

• How important is thermal modeling?

• Do I still need to test after FE analysis?

• What does the maximum junction temperature mean?

Having trouble getting started or just need some help? Just ask

©2008 RETRO-LEDs LLC | P:303.920.2040 |

©2008 RETRO-LEDs LLC | P:303.920.2040 |