|

|||

RotationalSize constraints |

InjectionQuantities apply |

SlumpedMaterial dependant |

VacuumMaterial dependant |

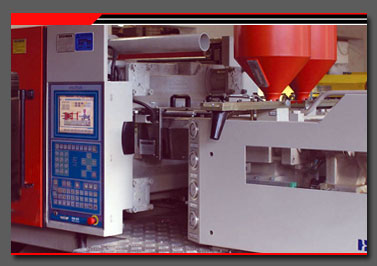

Molding

When choosing to mold products, we have the ability to use metal or plastic. This gives our engineering team the flexibility to pick the material that best fits the product. Another process we can use in prototype casting is metal injection molding or MIM. This process is often used for customers that prefer a “real” look and feel to help showcase new products during marketing or sales events. Polymers are typically sorted into high and low volume categories, which often determines the final molding process.

• What is tolerance stack-up?

• Is molding the best process for my product?

• Which features prevent designs from being moldable?

Not sure which process is right for you? Just ask

©2008 RETRO-LEDs LLC | P:303.920.2040 |

©2008 RETRO-LEDs LLC | P:303.920.2040 |